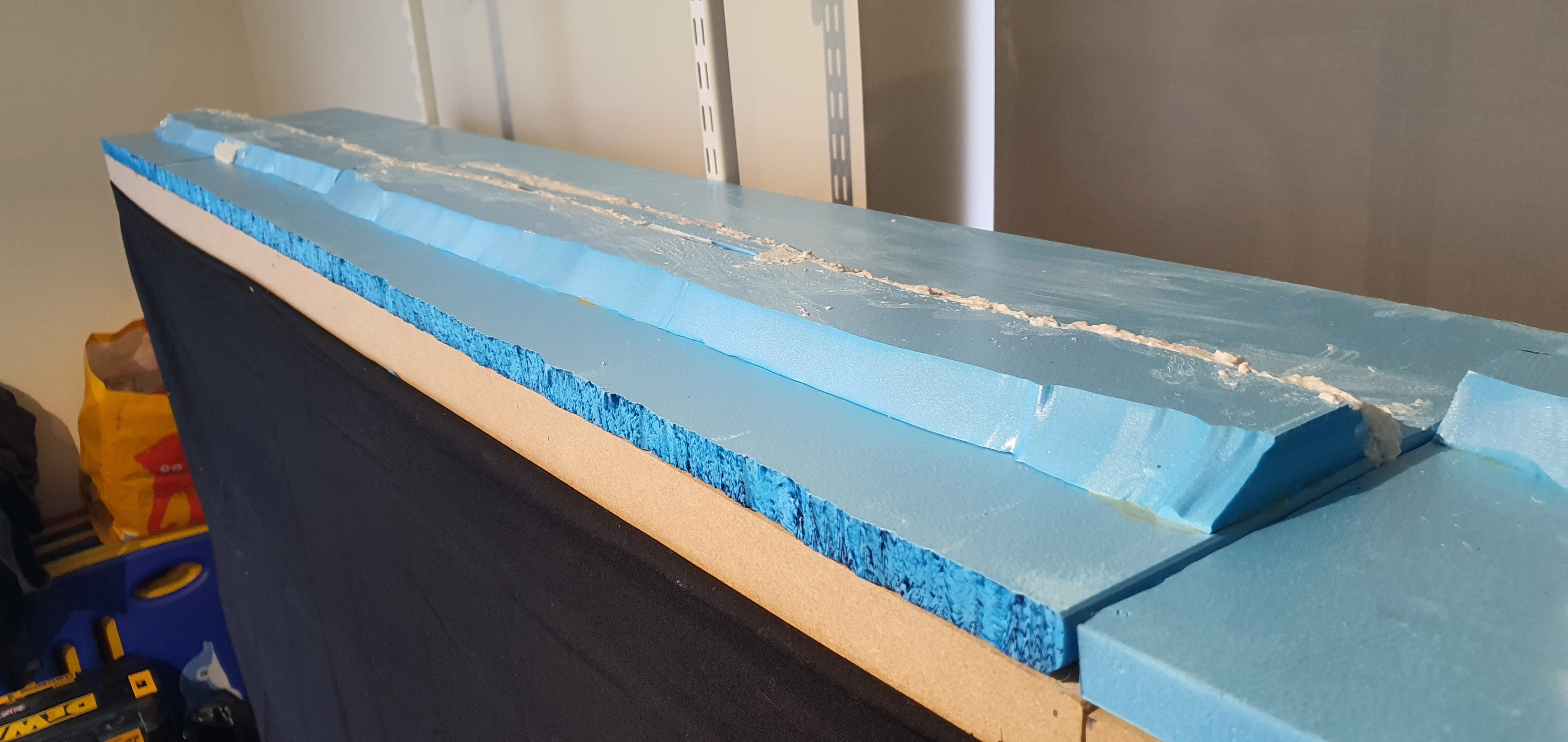

Before the sculptamold dries its really important to make sure that the road bed will fit. Mine didn’t so I had to cut away some sculptamold to fit the roadbed to it. Fortunatly the height of the roadbed and the height of the section that was left matched so you can’t see that this happened. Although the purists would notice that the drainage is missing from the side of the sub roadbed.

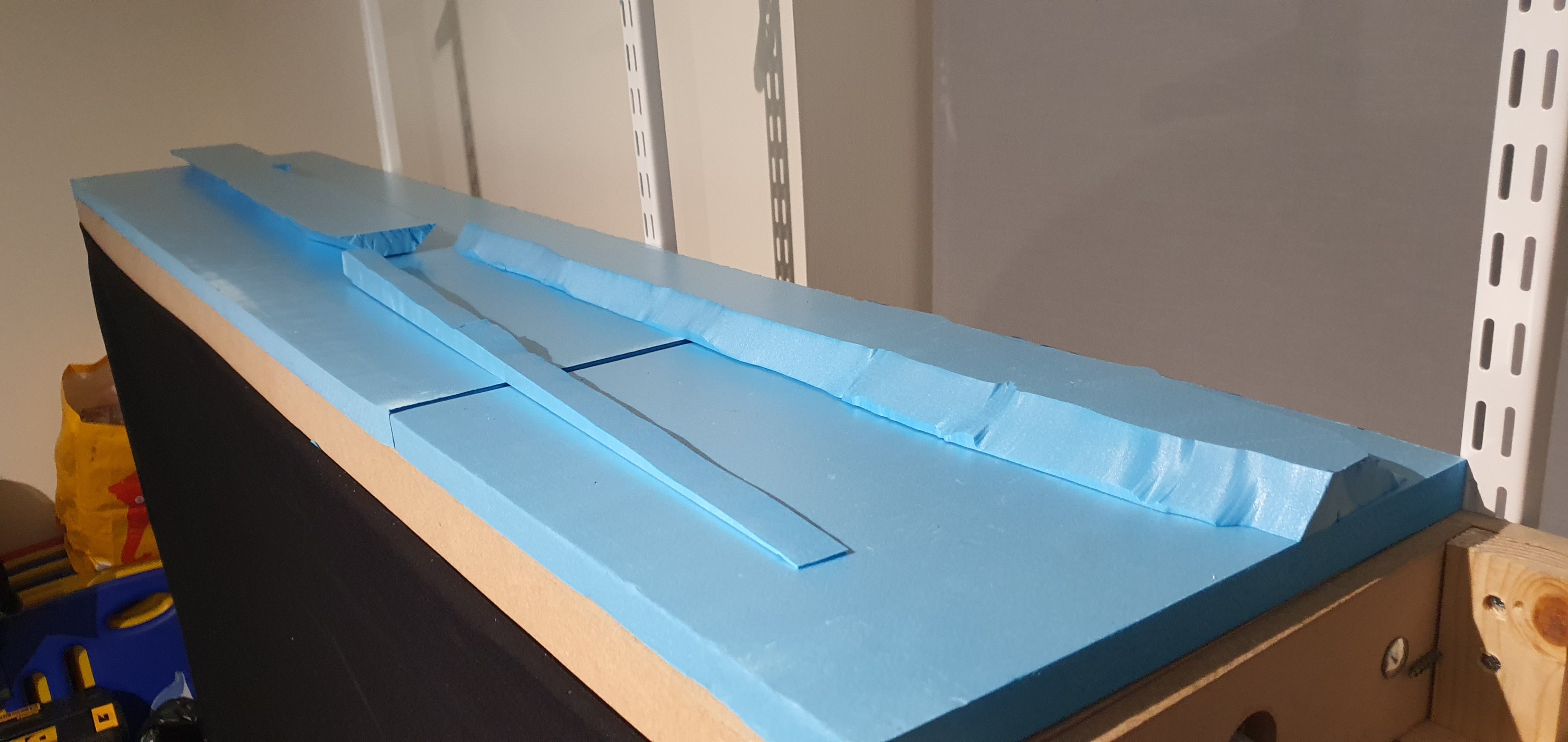

For the Waukesha sub I am using Woodland Scenics foam roadbed. Really becuse 1) I am not spiking so its not an issue that there is little resistance and 2) in my opinion this stuff deadens sound much better than cork.

I started with the roadbed on the incline using a 24″ straight section of roadbed you get 30 in a box.

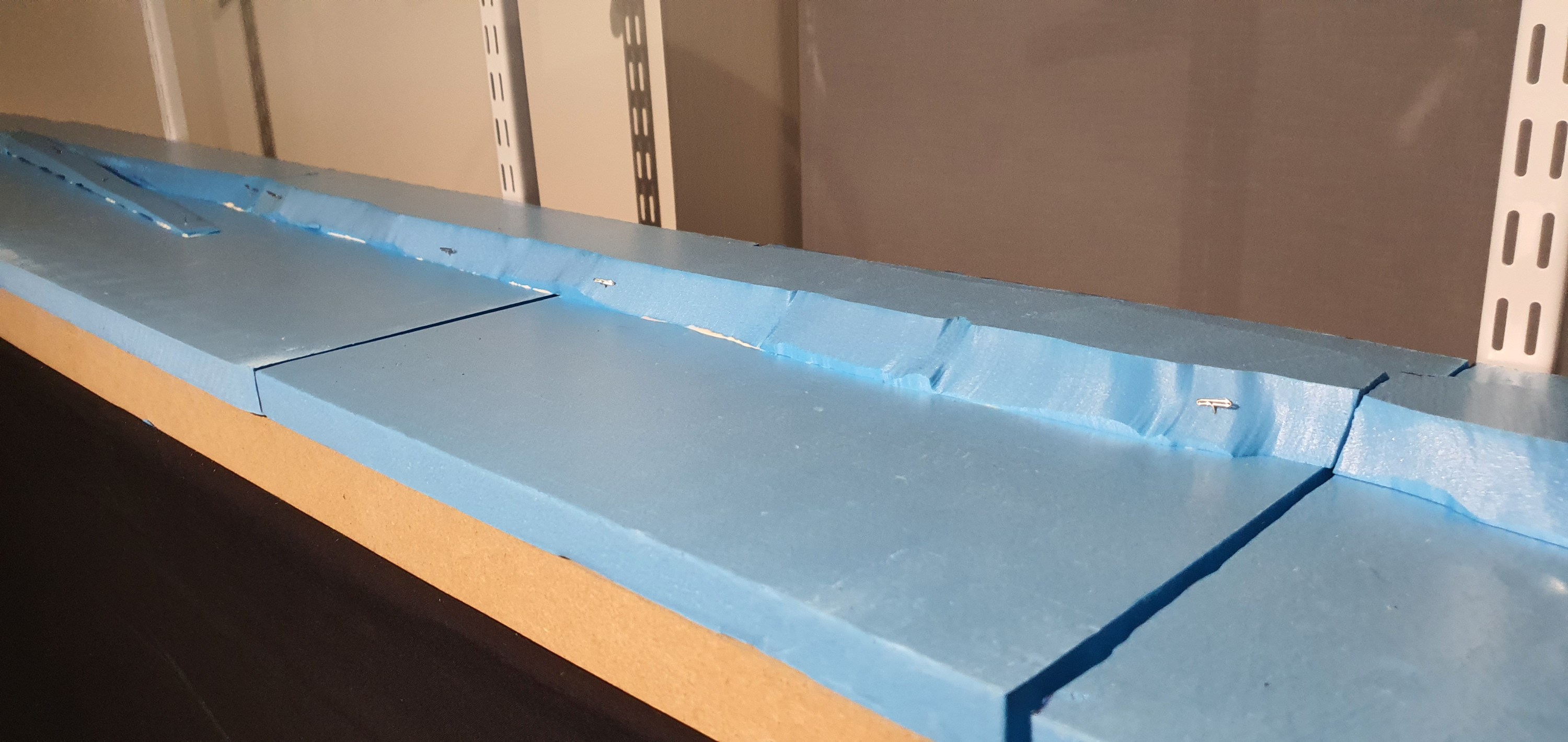

The WSOR roadbed, thats the bit thats at the rear is cut from a continuous 24′ roll of roadbed which is pefect for long straights such as this. The ackerville yard area is made up of flat sheets of roadbed and some straigh profile sections for the main approaching the yard and the siding which was added when the yard was built in 2001.

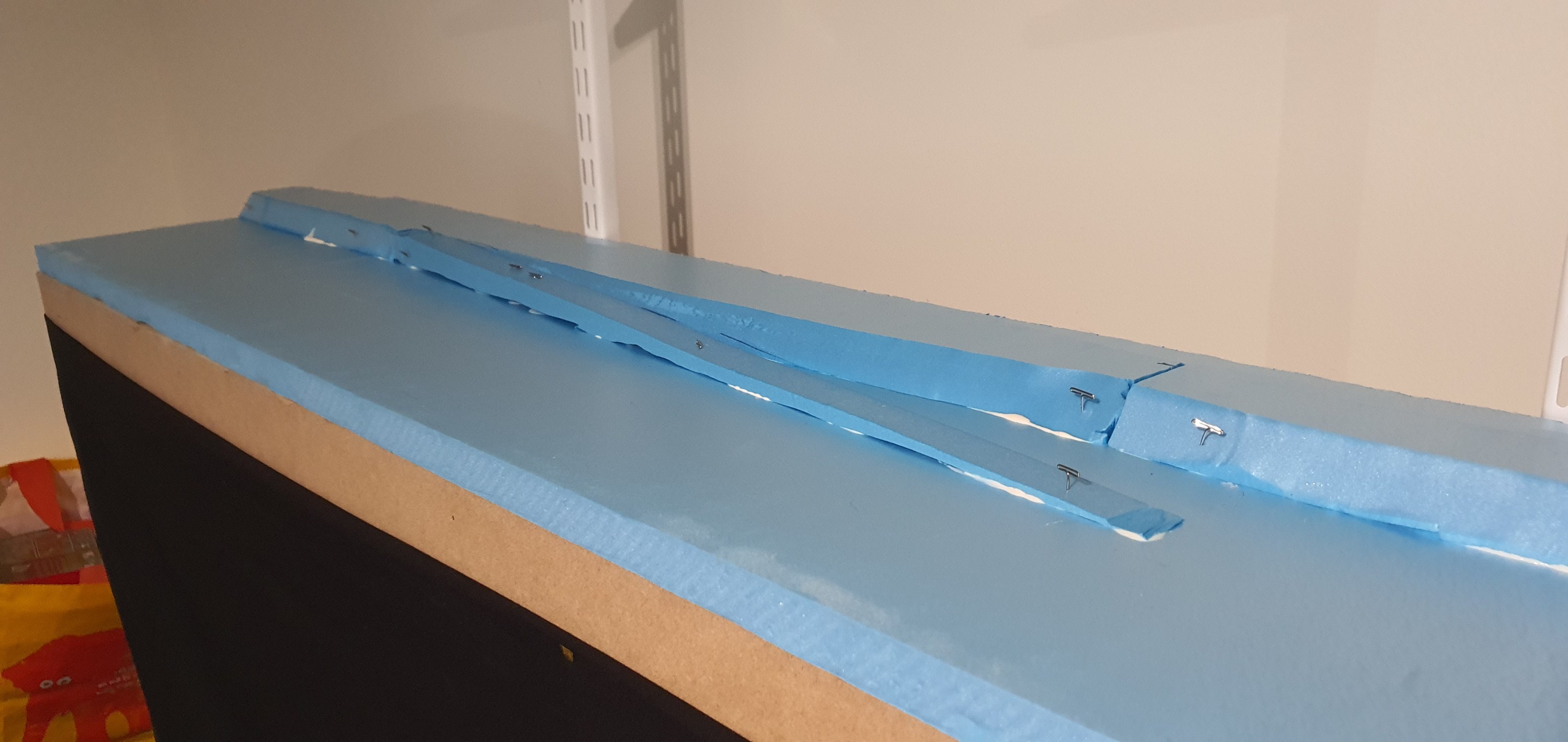

Once all cut to shape the sub roadbed was glued in place with PVA and held with Tpins while the glue dried.