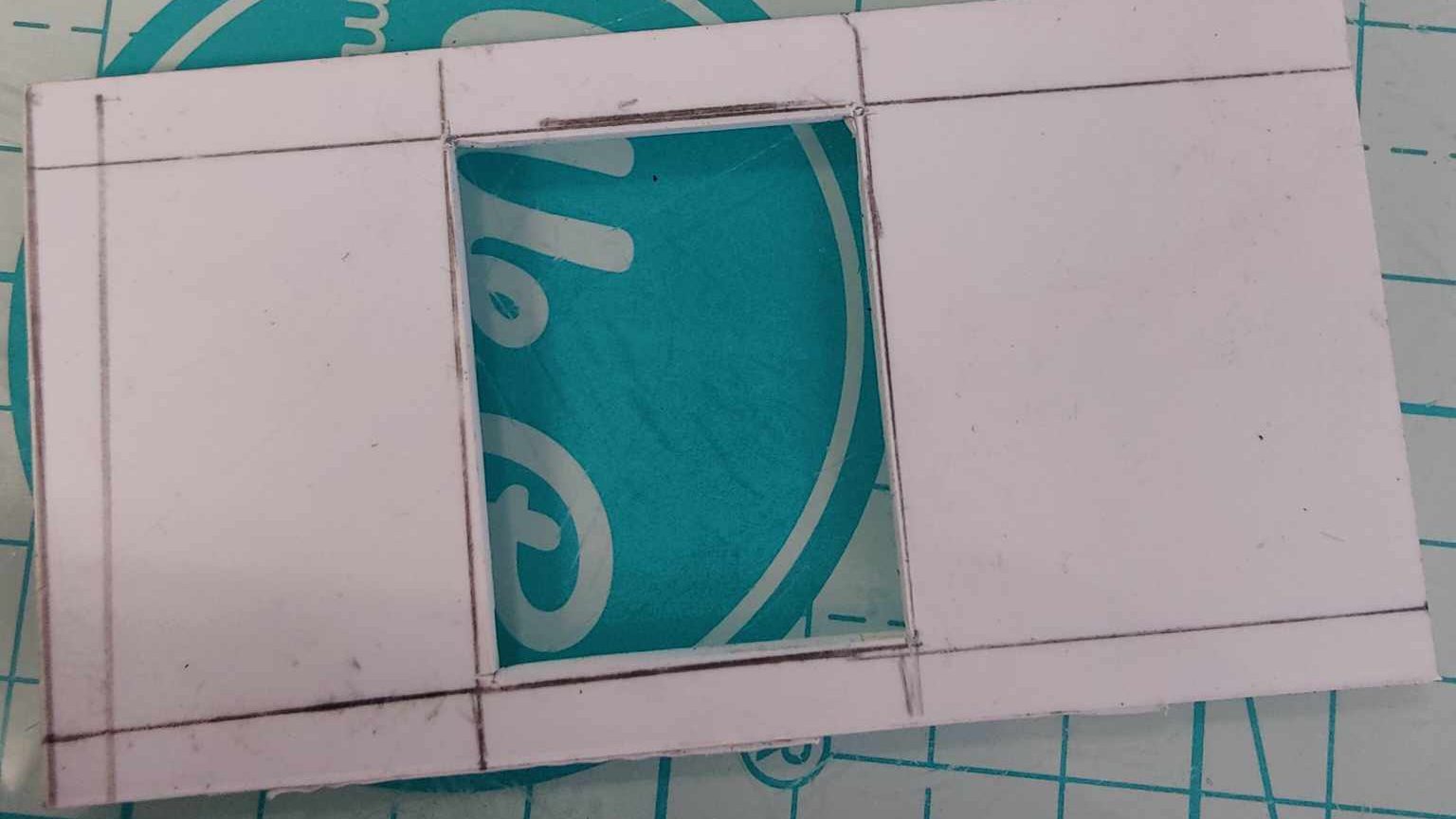

Have you ever found it really annoying when you’re scratch building something in styrene or wood, and you’ve got to cut out windows and doors? Yes, it’s one of the things I hate. When the corners, corners are a nightmare, right?

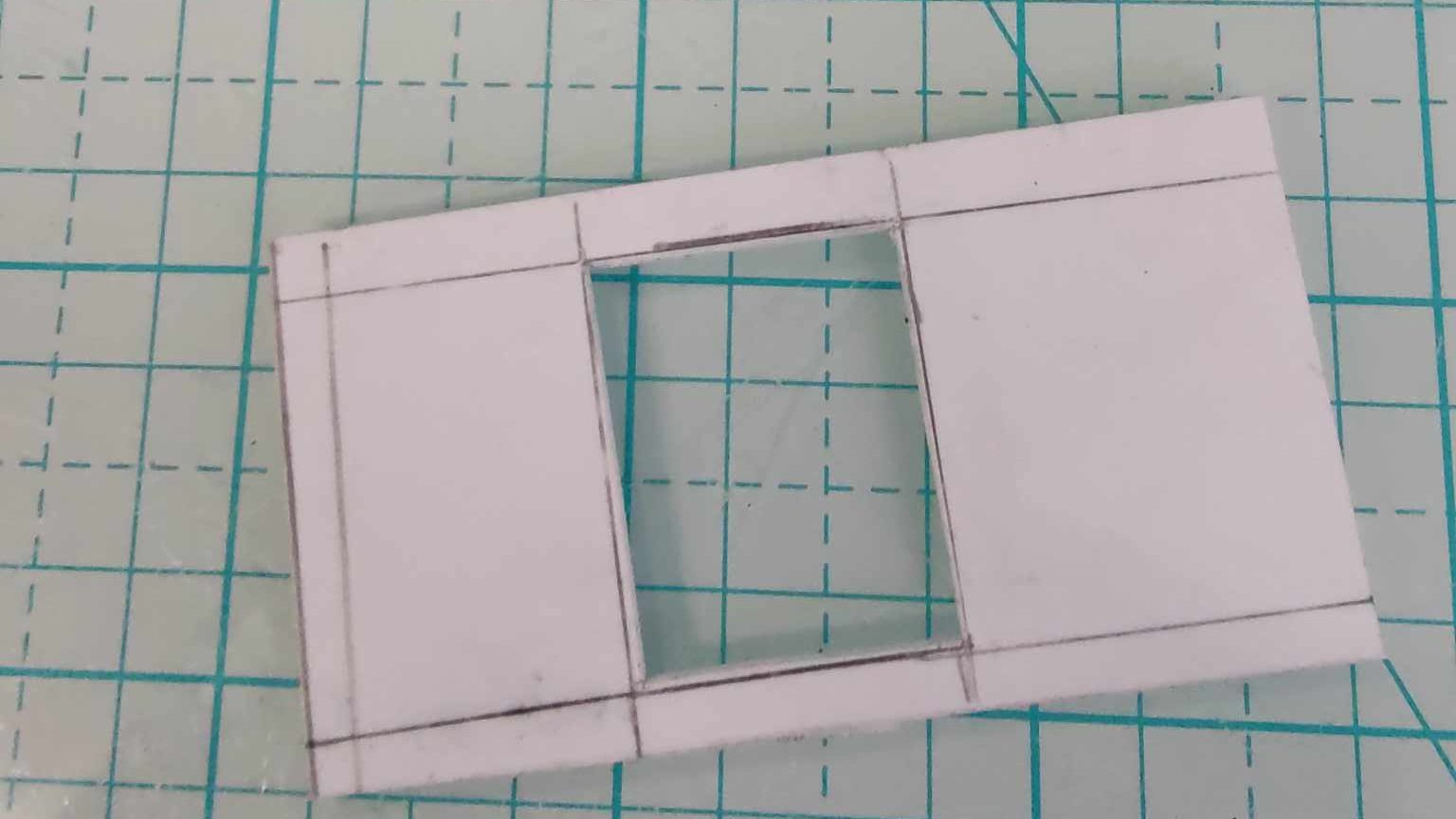

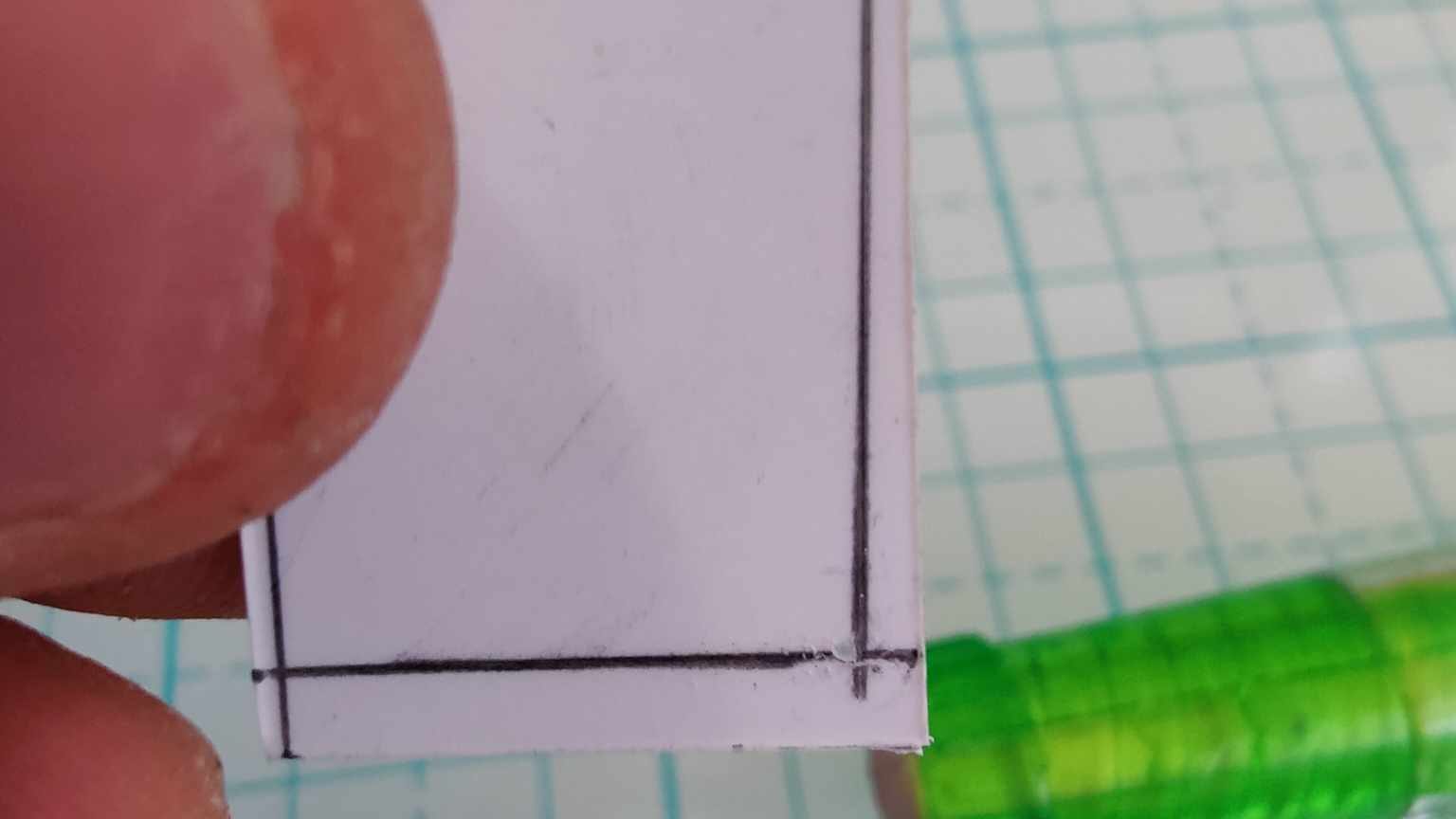

I can never get them to be all nice and neat. I have to file it. And it just makes me want to throw the model. Well, today’s tip is going to help you get better doors and window cutouts. OK? So once you’ve transferred the drawing of whatever you want to do onto the actual material, that’s really important, onto the back of the material.

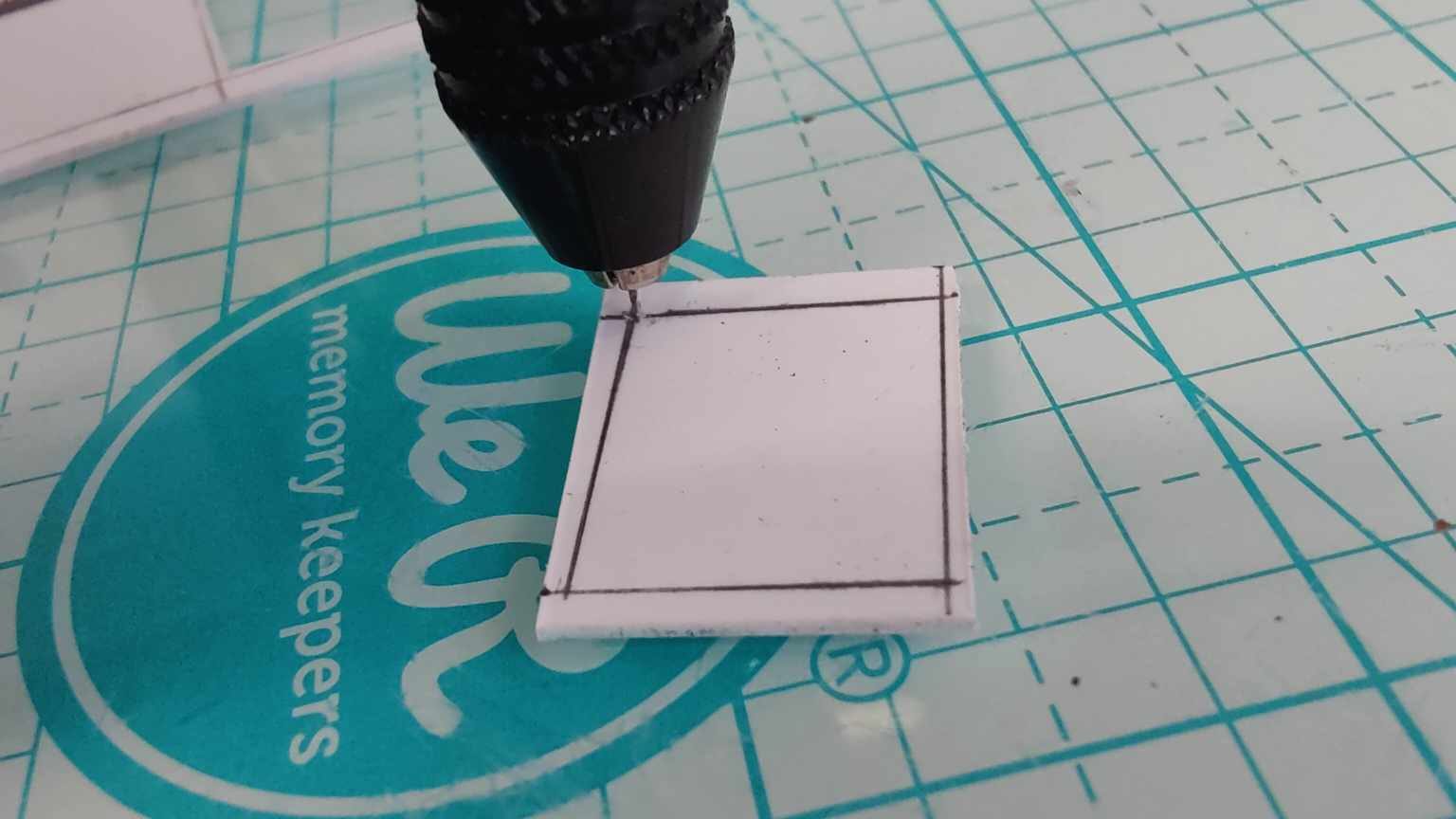

The best way to get nice square corners is to get a pin vice, pin vices. Yes. You can drill bit in. Find a really, really small drill bit about the thickness of an exacto knife blade, which is about we’re going to be British.

It’s about 0 .4 millimeters. It’s quite small, right? So you’re going to get a really small drill bit and you’re going to drill the exact point in the four corners or five corners, if it’s a funny shape window, the four corners of your window or your door, exactly where you want your corner to be.

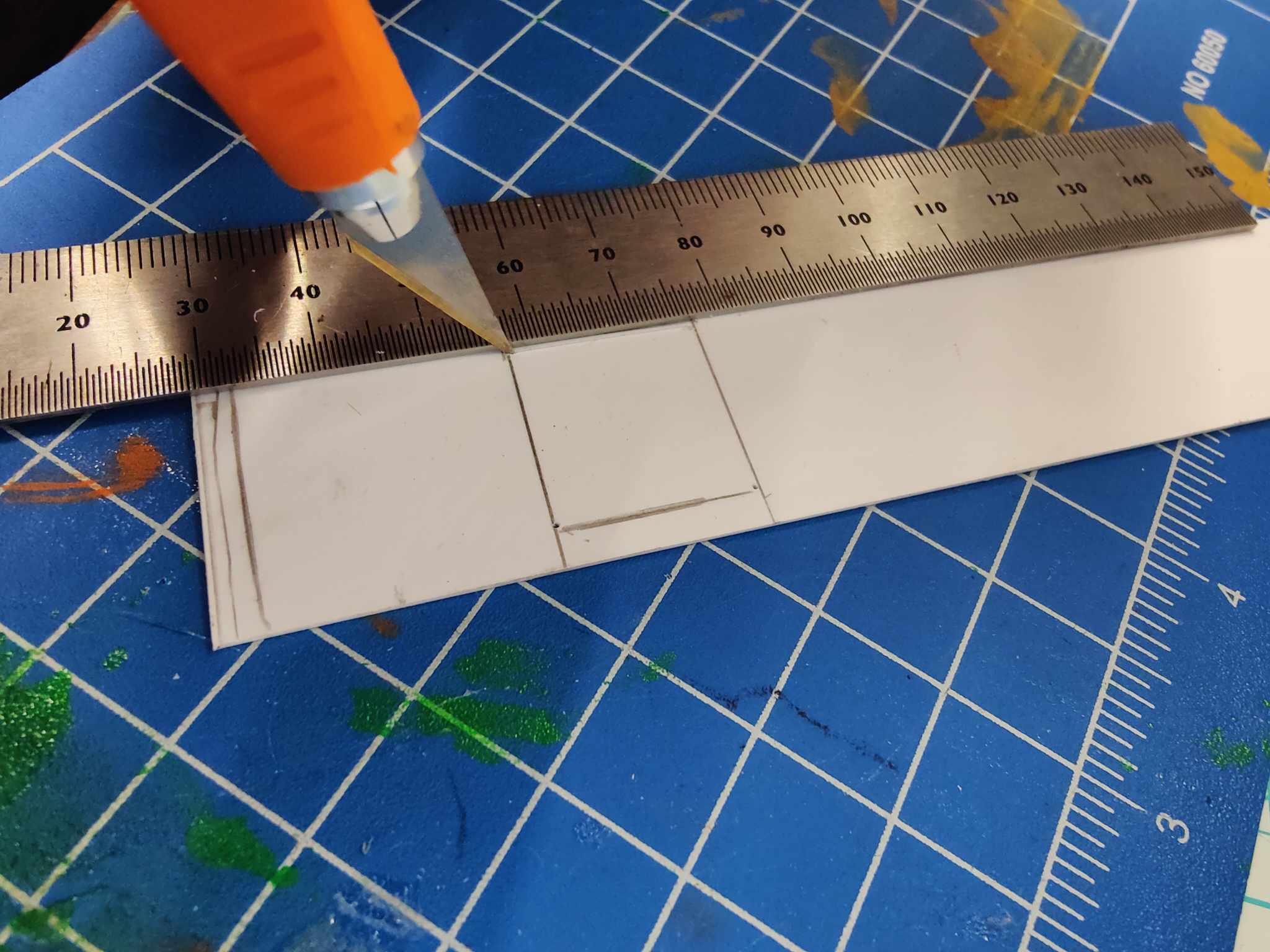

OK? Then you’re going to take your rule. You’re going to line up between your holes and you’re going to take really light passes with the exacto knife between them and it’s going to start opening that up.

But because you’ve got those holes, your exacto knife blade, unless you press really hard, isn’t going to kind of make that go over the line of where you want that corner to be. So you’re going to have a weird cutout.

And now I have an extra tip to add to this. OK. We don’t freehand with the styrene. You use a ruler as a guide. Ideally, yeah. So you get your ruler, you line it up between the holes and you run your knife.

But yeah, yeah, no, no freestyling, right? But the idea is if you drill those holes, your knife tip will just drop into them. And so it will stop you from going over the lines.

That’s one of the hardest things when you’re cutting out a door or window is to make sure that the knife cut stops because you cut him through quite thick material. Yeah, you’ve got to make multiple passes and no ones, no one is perfect at doing this.

There are tools that you can get that can cut out. I think micromark do a tool where you can kind of like a chomper and it’ll chomp you a perfectly square hole. But this this method is like totally tried and tested.

So if you’re an N scaler, though, that thing that cuts out is going to cut out a really big window. Yeah. So when you’re modeling in the smaller scales, z and n, you want to use a really fine, fine hole.

Now, depending on the thickness of your material, if if like me, and you are a diabetic, you will have a few hypodermic needles about. I don’t suggest you go out and find your nearest bad neighborhood, just go and ask for a needle at your nearest pharmacy.

But if you’ve got access to a kind of hypodermic needle, you can use a fresh, clean, sterile hypodermic needle and push it through the material. Certainly in soft, soft, or styrene, but you’re kind of safer just using a very, very small brush that you can, brush, drill that you can, you can finally control.

Get those holes in the four corners, then just go around with your blade and that will get you nice and square doors and windows every single time. And that is our top tip for this week. See you again on the workbench podcast.