Well still no saw 🤬 so maybe I can get some track down. This is a three stage process to be honest. We’ll get the track cut to length and fitted. Then we’ll solder feeders and finally glue it to the roadbed. Then it’s electrical stuff for us to get on with.

I always start by putting my turnouts in place. Then I hold them in place with t-pins and measure each piece of flex that will go between them.

On peco turnouts you need to remove these spare ties/sleepers. You will put them back later when the track is glued down.

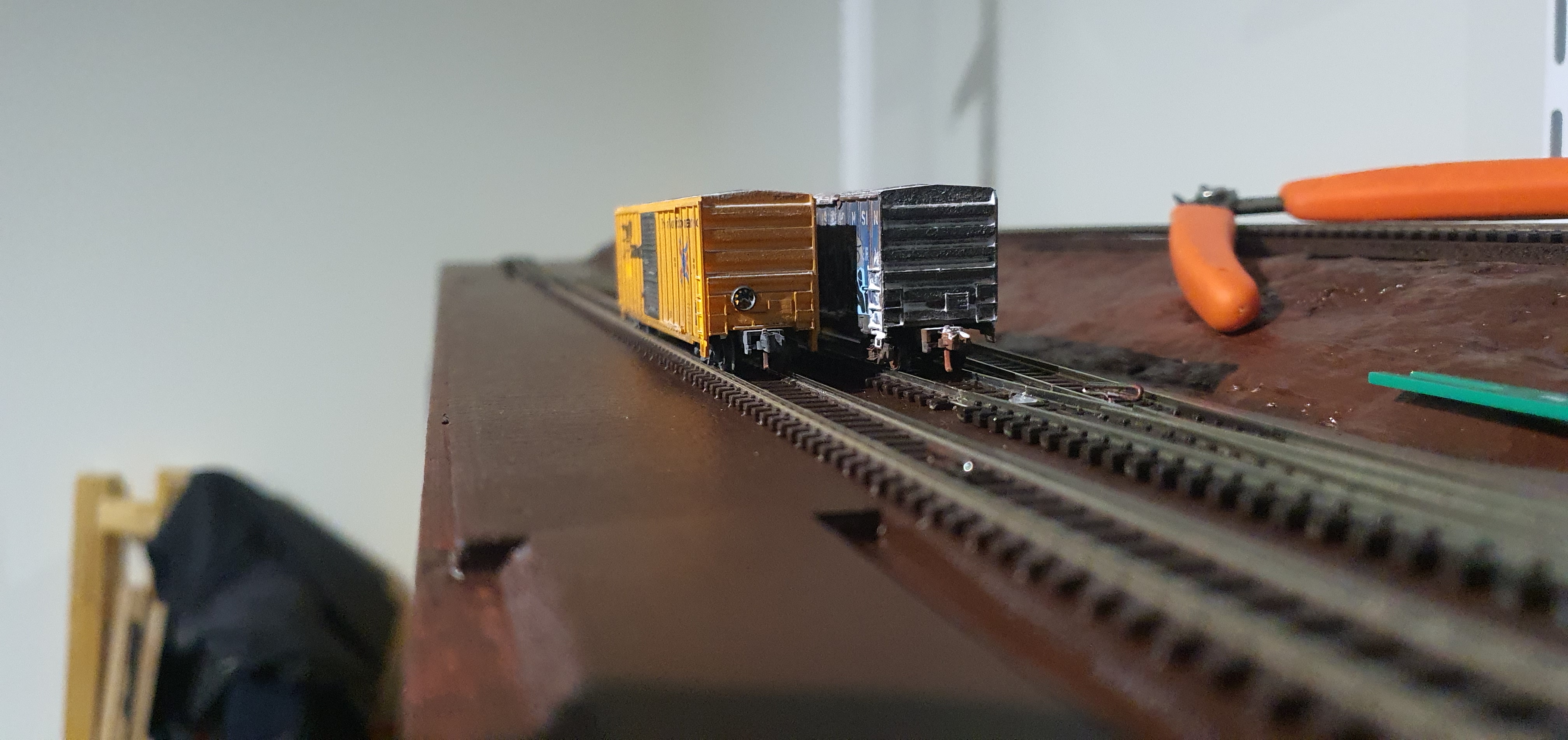

Here you can see the first sections of track starting to go down. I used a tracksetta radius to create curves in the flex and straight section to straighten the flex as its always got kinks in it when you lay it.

The cut flex is held with t-pins

Then its on to checking clearances to make sure nothing is too close together.

Things get jiggled about until we have something that looks like our track plan with no unsightly gaps.

Right now time to get feeders in and make some holes for the turnout control wires.

Call back tomorrow to see more progress. Gordy