As I said in my pevious post materials are low on the ground here at the moment, there are plenty of wee jobs to be getting done but there are not enough materials to actually finish anything. Therefore this is a post about drilling a hole so thats your hint to run give up reading the rest of this update.

The Plan

To support my backscenes and upper deck I need to use something, there are also challenges in so much as this is a modular layout it may have to come apart to move to a new room in the future. So we need to bear that in mind. we also don’t want to damage the walls of the room and don’t want anything to thick or heavy making the layout smaller.

Shelf layout folks have for a long time used twin slot shelving to mount their layouts and the same theory can be used to make a double deck modular layout. Of course we need to be mindful or the weight we are adding above deck one. By adding the short section of twin slot u channel we are adding a lever and anyone that has used a prybar to rip open a pallet will know the pros and in this case cons of doing that. Whatever force is applied to the uprights will be trying to rip apart the bottom module, so care is needed.

Backscenes & Upper Decks

The back scenes will be 3mm MDF i am still not sure on if these will be painted or photos but as I am planning on a winter scene for the layout then I think all options are open. Otherwise I would be reccomending photo backscenes all day long. Whats important here though is weight and well there won’t be much acting on the support from the backscene.

The upper deck will only be 120mm wide and cut from 15mm OSB this is heavy but its strong and won’t need any other supports underneath that means we can have that rail height only 250mm above our lower deck and have the backscene 228mm (9inches) high below it. Again not much weight. I may add a lighting deck to form a shadow box at the very top of the upright and so long as nothing is placed on here I think we will be fine. Also using metal uprights means I can use magnetic tape to have an easily removeable backscene without needing to dismantal the layout.

Where to Start

Well as always material is in short supply here in Orkney and I could only get 11 636mm uprights. I have used Elfa uprights for a number of years and these can be purchased in the UK from Iornmongrey Direct. It doesn’t really matter where you get your materials from but its important to stick with the same brand. Not all twin slot is created equal and pretty much no two brands play nicely together. Elfa is great for model railroaders because they do brackets from 120mm up to over 500mm which is really a very wide shelf layout. Also being 2mm thick steal they are strong and support a huge 55kg per bracket.

As we only have 11 of these I am also going to start with those in the most awkward place on the layout to access above the workshop area. This will involve dismantling part of the layout but once done there shouldn’t be a reason to repeat doing this for any future jobs as the magnetic tape will hold the backscene in place.

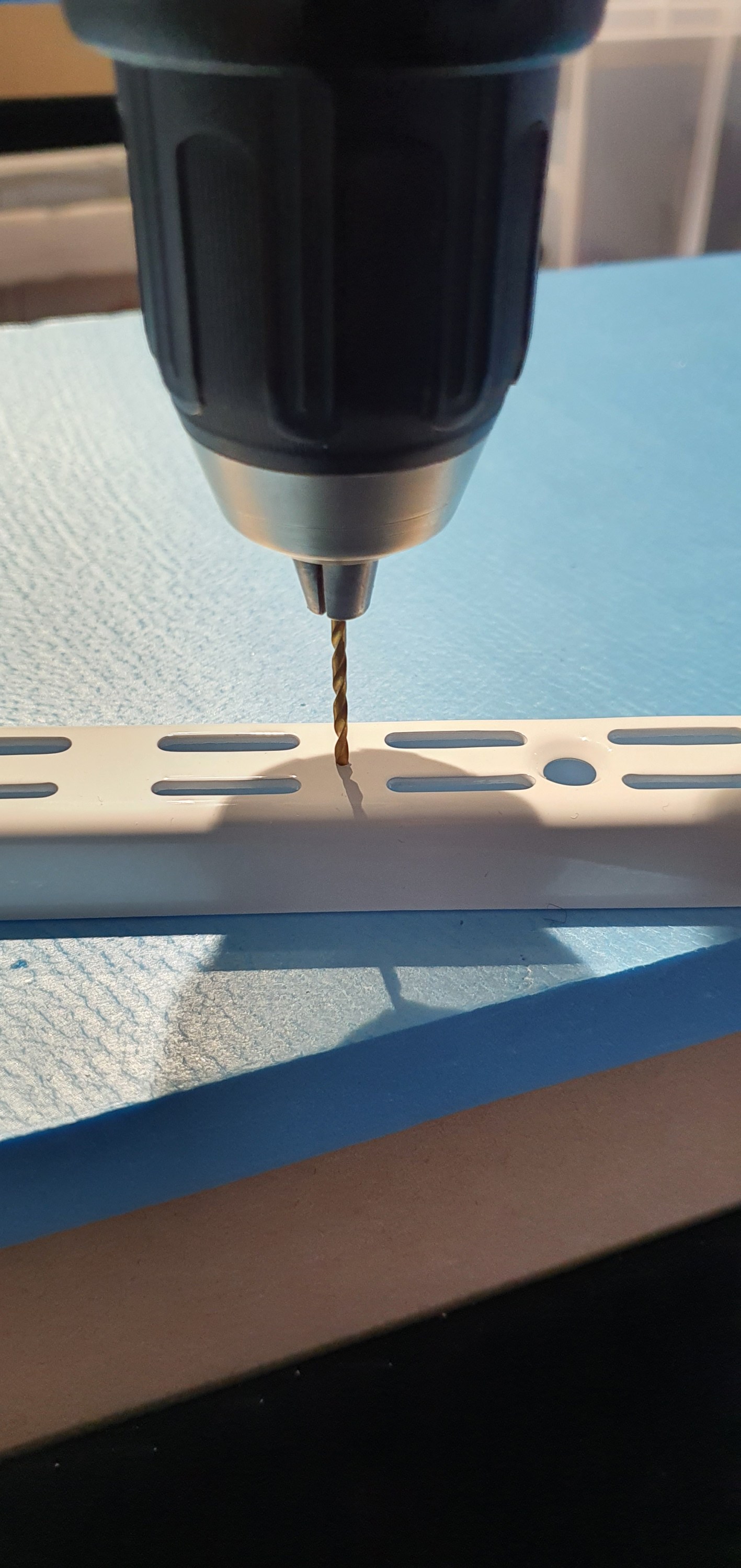

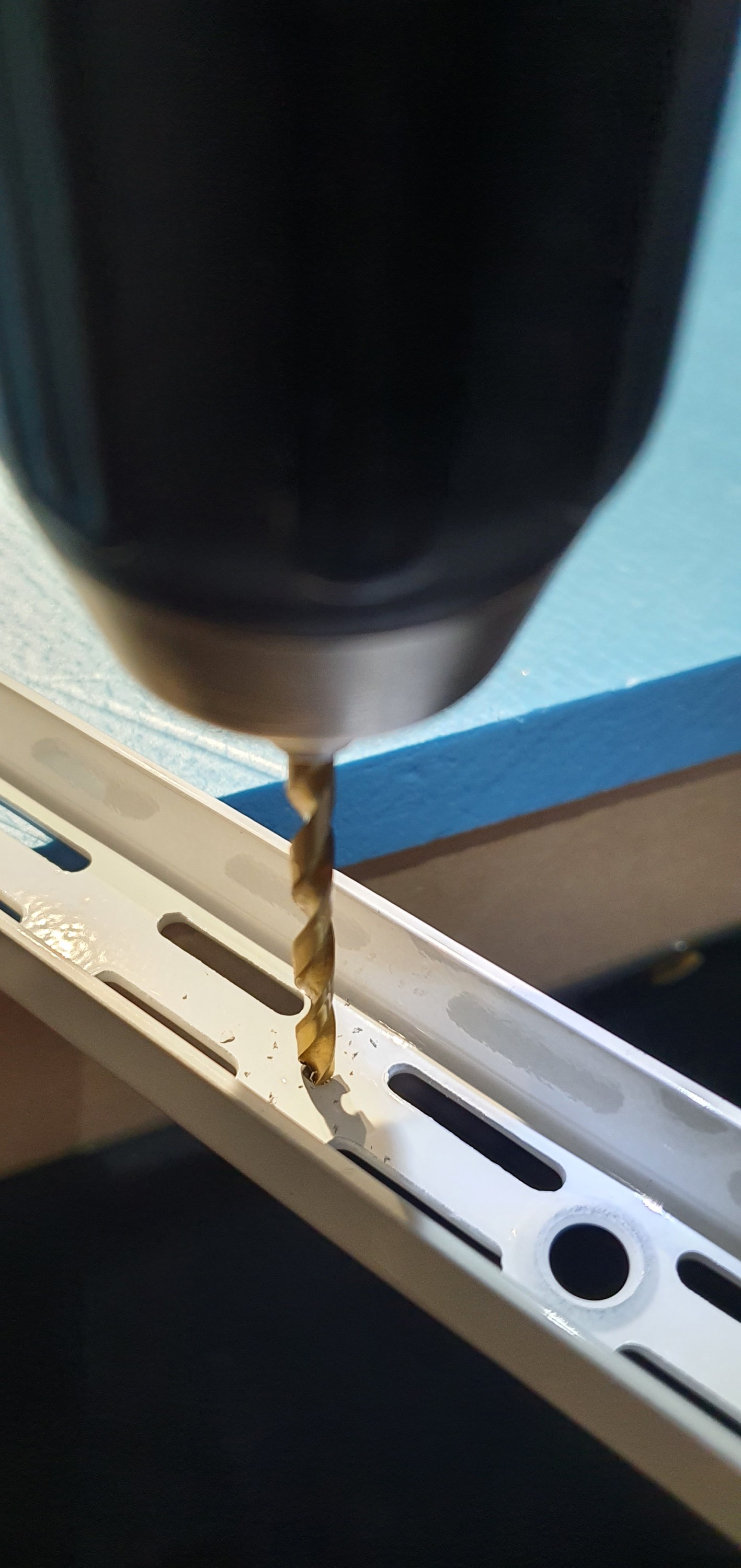

Out of the box each upright has three holes for screws 290mm apart. Thats grand for on a wall but for me that would mean only one screw per upright and thats a little much I think. So its time to get to drilling a hole. How much you’ve been looking forward to a blog post on drilling a hole, well here it is.

Right we have 11 of these now just enough to do along that back wall above the workbenchs, now I need to find an extra pair of hands to dismantle the layout.

Till tomorrow 🙂